Theory of Sampling (TOS)

It is not only about analysis – it is just as much about what comes before: Theory and Practice of Sampling heterogeneous materials and processes (TOS)

The common characteristic of all naturally occurring as well as all technological and industrial resource materials (rocks, alloys, biomass and environmental samples, aggregates, mineralisations, ores, concentrates) is heterogeneity, which has a much more complex spatial distribution that what can be encompassed by classical statistics. While lots and materials differ seemingly without restrictions, it turns out that the exact same representative sampling principles can be applied to lots of all sizes, forms, composition, and at all scales.

A Complete Foundation

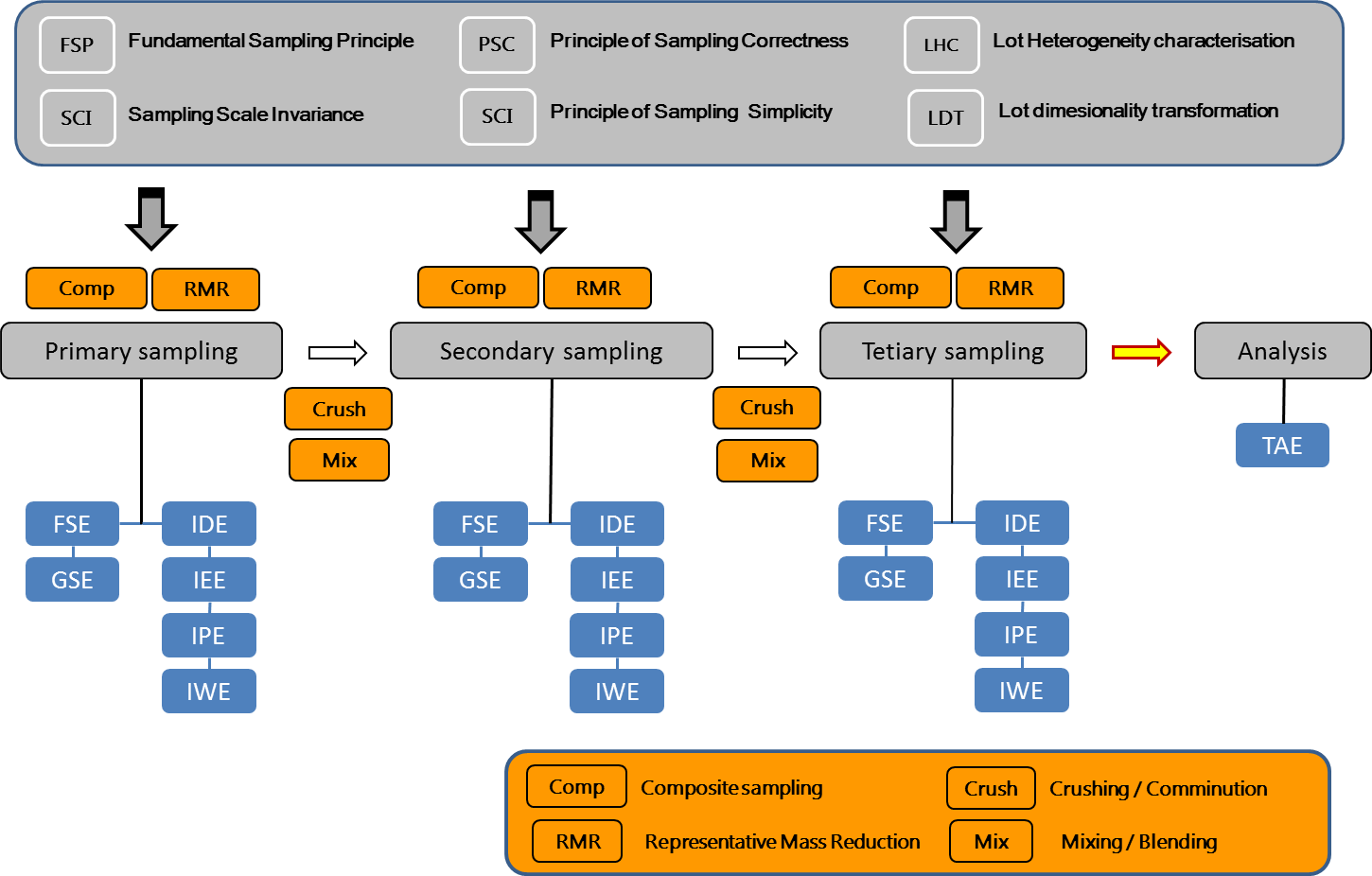

The Theory of Sampling provides a complete description of heterogeneity and all error types involved in sampling of materials and processes as well as the necessary tools for their evaluation, elimination and/or minimization. The basic principles of the Theory of Sampling (TOS) are sufficient to understand all critical sampling error components from lot-to-analysis, providing a complete foundation to identifying faulty, inefficient, or suboptimal sampling procedures – and which improvements possibilities are available.

The Sampling Process

A set of six Governing Principles (GP) and four Sampling Unit Operations (SUO) cover all necessary practical aspects of representative sampling and provides a comprehensive framework/toolbox for plant and field personnel, process engineers, laboratory personnel, quality units as well as supervisors and management who has to make critical decisions based on valid analytical results.

The singular most important issues in this lecture is that the sampling bias is of a fundamentally different nature than the well-known analytical bias – unfortunately negating all attempts of ‘bias-correction’ in sampling. Instead TOS provides a set of practical ways to achieve “sampling correctness” (unbiasedness) by informed understanding, design and implementation of the sampling process. TOS gives full insight into how to guarantee that all primary sampling, and subsequent sub-sampling (splitting) and sample preparation before analysis is documentable as representative (procedures, equipment, maintenance).

After the critical primary sampling step, correct (unbiased) mass reduction/sub-sampling in the laboratory is equally important in order to ensure valid analysis analytical results. It is often neglected that the Total Sampling Error (TSE) is by far the dominating contribution to the total Measurement Uncertainty (MU), often 10-50 X larger than the Total Analytical Error (TAE). TOS deals with both stationary lots as well as dynamic process lots and has a special focus on setting up experiments to estimate and characterise heterogeneity (replication experiments and variographic experiments).